Amps Tools India

Carborundum Cut Off Wheel

Carborundum Cut Off Wheel

Couldn't load pickup availability

A Cut-Off Wheel is a thin, circular abrasive disc designed for cutting through various materials such as metal, stone, and ceramics. These wheels are commonly used with angle grinders, die grinders, and stationary cut-off saws in construction, metalworking, and fabrication industries.

Key Features:

-

Material Composition: Typically made from abrasive materials like aluminum oxide or silicon carbide, bonded with resin to form a rigid disc.

-

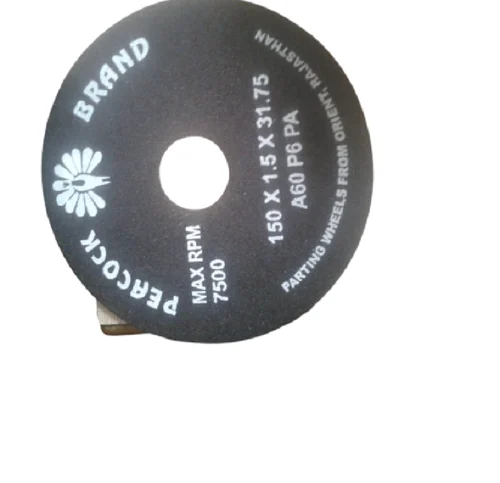

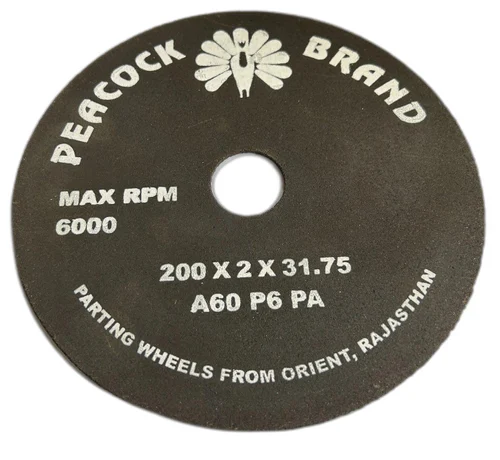

Thickness and Diameter: Available in various diameters (commonly 4.5 to 14 inches) and thicknesses (ranging from 0.04 to 0.125 inches), allowing selection based on the specific cutting application.

-

Reinforcement: Often reinforced with fiberglass layers to enhance durability and reduce the risk of breakage during operation.

Applications:

-

Metal Cutting: Efficiently cuts through steel, stainless steel, aluminum, and other metals, making them essential in metal fabrication and automotive repair.

-

Masonry Cutting: Specialized cut-off wheels are designed to cut through concrete, brick, and stone materials.

-

Pipe Cutting: Ideal for cutting metal pipes and tubing in plumbing and construction projects.

Safety Considerations:

-

Proper Mounting: Ensure the wheel is correctly mounted on the tool, with the appropriate arbor size and flange support.

-

Operating Speed: Do not exceed the maximum RPM rating specified for the cut-off wheel to prevent accidents.

-

Personal Protective Equipment (PPE): Always wear safety goggles, gloves, and hearing protection when operating cut-off wheels.

-

Inspection: Regularly inspect the wheel for cracks, chips, or wear before use, and replace if any damage is detected.

Selecting the appropriate cut-off wheel involves considering factors such as the material to be cut, the tool being used, and the desired finish. Consulting with manufacturers or industry experts can aid in choosing the right wheel for your specific application.

Share